In the demanding environment of a hot plate rolling mill, precise profile measurement of plates is essential to ensure quality standards and operational efficiency. When a customer approached Sapotech with the need for such a system, Sapotech took action to meet the...

News

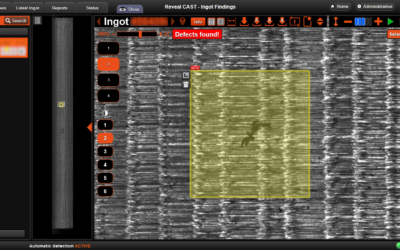

Sapotech’s Reveal CAST system continues to thrive in Japan!

Sapotech’s Reveal CAST system continues to enhance surface inspection processes in Japan. Installed on a grinding machine used for processing steel ingots of various shapes and sizes, the Reveal CAST system has not only met but exceeded the high performance...

Sapotech and Intocast at AISTech2024

Sapotech and Intocast participated together at the AISTech 2024 fair last week, showcasing the new strategic partnership. AISTech was a success, and we are particularly pleased with the enthusiastic reception of the news. This partnership opens new opportunities for...

Success stories

Sapotech successfully commissions surface inspection system in Japan

Sapotech’s first Reveal CAST system in Japan was successfully commissioned at the beginning of January. The first Reveal CAST surface inspection system has been successfully taken into use in Japan. The system was installed on a grinding machine that...

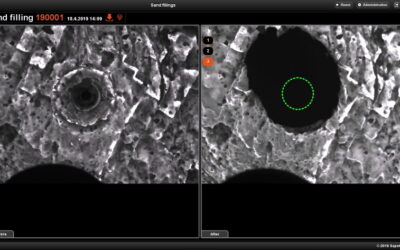

Yet another AI powered application for Reveal TAP!

High free opening rate of ladles is a key factor during steelmaking to keep steel quality high and for safety purposes. To ensure high opening rate, steelmakers use filler sand to avoid a direct contact of the liquid metal with the slide gate-system of the steel...

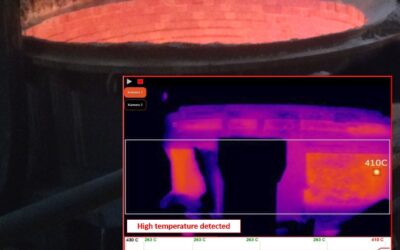

Reveal TAP delivered, installed and commissioned for a totally new location

This is a new customer who wanted to improve its process operation by monitoring the temperature of the ladle outer walls and detect on time any critical heat. Our solution IR cameras with high resolution were used so there was a real time visualization and monitoring...