Sapotech’s Reveal CAST system continues to enhance surface inspection processes in Japan. Installed on a grinding machine used for processing steel ingots of various shapes and sizes, the Reveal CAST system has not only met but exceeded the high performance...

Success stories

Discover how our solutions have made a difference by reading about our customers’ successes. Explore our success stories to see real-world examples of how our technologies have transformed operations and delivered exceptional results over the years.

Visionary Alliance: Sapotech and INTOCAST Team Up for AI Real-Time Monitoring Solutions

We are excited to announce a strategic partnership between Sapotech and Intocast AG, a German company with over 40 years of expertise in refractory products and plant engineering on a global scale. Together, Intocast and Sapotech will challenge the current ways...

New advancements for Sapotech’s Deep Learning technology

In august 2022 Sapotech announced the Reveal CAST – Deep Learning module for surface defect detection. Today, in 2023, the module has now become our de facto module for all future Reveal CAST deliveries and can be easily retrofitted to all our existing installations...

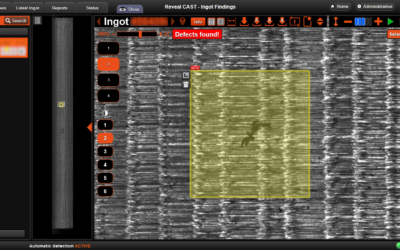

Sapotech successfully commissions surface inspection system in Japan

Sapotech’s first Reveal CAST system in Japan was successfully commissioned at the beginning of January. The first Reveal CAST surface inspection system has been successfully taken into use in Japan. The system was installed on a grinding machine that...

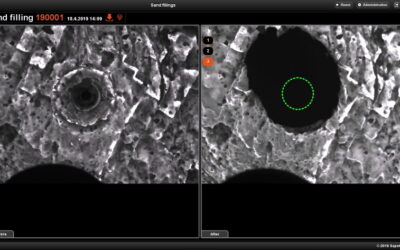

Yet another AI powered application for Reveal TAP!

High free opening rate of ladles is a key factor during steelmaking to keep steel quality high and for safety purposes. To ensure high opening rate, steelmakers use filler sand to avoid a direct contact of the liquid metal with the slide gate-system of the steel...

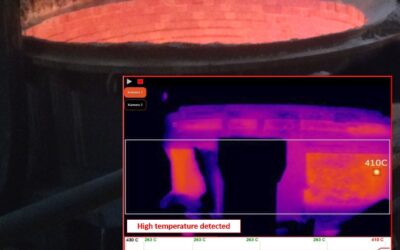

Reveal TAP delivered, installed and commissioned for a totally new location

This is a new customer who wanted to improve its process operation by monitoring the temperature of the ladle outer walls and detect on time any critical heat. Our solution IR cameras with high resolution were used so there was a real time visualization and monitoring...

Reveal CAST helps our customer save energy and production costs

Our customer was facing some difficulties in its steel production. During the continuous casting process, one of the caster rolls was causing defects on some of the slabs surfaces. Our solution After the root cause of the defect was found, our customer, with the help...

Reveal CAST is installed in record time!

Our customer needed to visualize and inspect the surface condition of their slabs during production from both top and bottom side. He also wished this installation to be done quickly so it wouldn’t interfere or slow down the steel production. Our solution Reveal CAST...

Reveal TAP for monitoring of Ferrochrome Submerged Arc Furnace (SAF)

One of our key customers wanted to distinguish between the metal and slag that was pouring out of its arc furnace so there could be a clear vision of the molten stream and under safe conditions from the control room. The customer needed specifically to monitor two tap...