Sapotech is launching an article series on its solutions, where a comprehensive overview of Reveal TAP and Reveal CAST is provided, along with a detailed exploration of their various application areas. The series begins with an introduction to Reveal TAP.

In this article, Reveal TAP is discussed at a general level, providing a brief overview of its primary applications.

Description

The Reveal TAP system, incorporating machine vision, is designed for comprehensive monitoring, documentation, and analysis of metal processes. This system is characterized by its integration of various sensors, cutting-edge imaging technologies, machine learning and algorithmic processing.

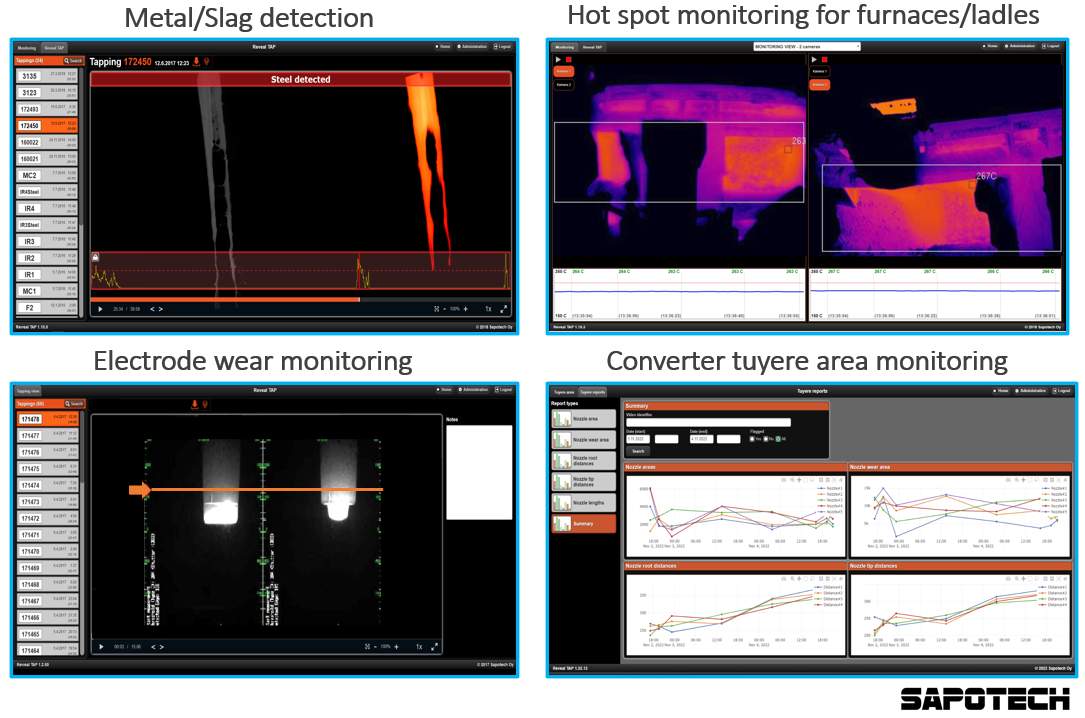

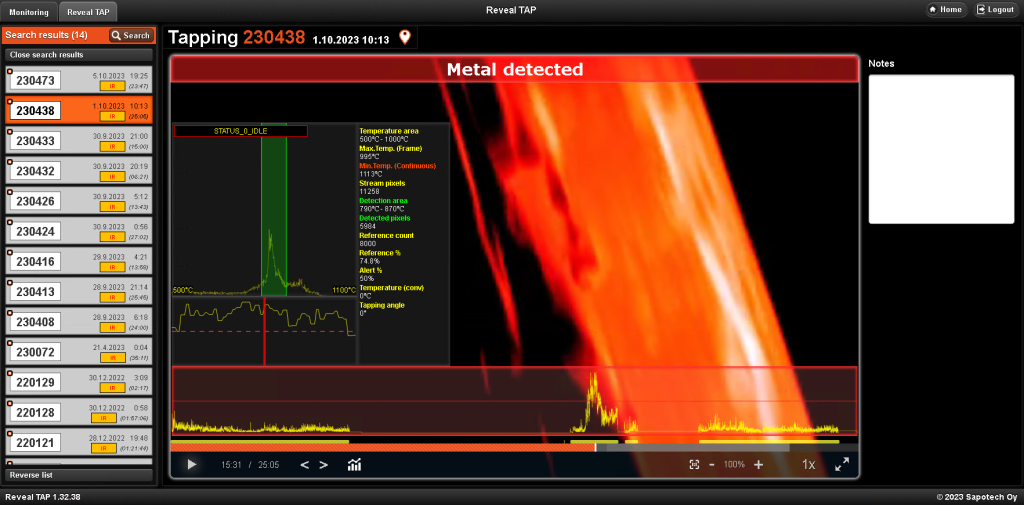

The Reveal TAP system provides real-time visualization of the various metal processes, enabling operators to have a complete overview of the operations. The system can reveal small details that might otherwise be unnoticed in typical conditions. Advanced algorithms derive important insights from the sensor data, which is delivered to operators in both numerical and visual formats, giving them the necessary information to address specific challenges effectively. Machine learning and image processing algorithms are introduced to help control the process and to give automatic alert when specific process anomalies appear (Figure 1).

Figure 1. Reveal TAP user interface – Metal/Slag detection.

The Reveal TAP hardware is a compact and efficient system, carefully designed for seamless integration within steel, copper, and other metal plants. It consists of thermal and/or monochrome cameras (depending on the application) with specialized enclosures, ensuring their durability and reliability in harsh conditions present in molten metal processes. In addition to cameras, the system also includes control/field cabinet, Reveal TAP analysis software, and flexible data storage options. These choices encompass long-term data storage in Sapotech cloud or on local servers, depending on the customers’ preferences. The hardware also includes a server-based application accessible from any location within the metal plant, enabling real-time monitoring from anywhere within the facility. In figure 2 below, the key hardware components of Reveal TAP are presented.

Figure 2. The key hardware components of Reveal TAP. Next, a few of the most common applications of Reveal TAP are discussed.

Application

The Reveal TAP system is versatile and can be used in a wide spectrum of applications in metals production. Its flexibility allows for customized configurations, ensuring it aligns precisely with each customer’s unique requirements. Below, some of the key application areas are introduced, highlighting the system’s potential to be used in various molten metal processes:

- Metal/slag detection: Based on the use of high-resolution infrared cameras and adaptable detection algorithms, Sapotech’s metal/slag detection system detects the metal/slag transition during the tapping process and alerts the operators. The system has been successfully implemented for different metals and can be used in processes like Argon Oxygen Decarburization (AOD), Electric Arc Furnace (EAF), Basic Oxygen Furnace (BOF), and copper converting. The advantages resulting from automatic metal/slag detection include improved product quality and increased yields.

- Hot spot monitoring for furnaces/ladles: Infrared cameras are used to measure the temperature of the outer steel shell of furnaces, ladles, and other critical assets in metals industry. The system provides real time temperature measurements and temperature trends to avoid breakouts. The system outputs can also be used to optimize the lifetime of the refractories.

- Converter tuyere area monitoring: For converters such as AOD and chrome converter, the Reveal TAP system offers process monitoring as the changes in the tuyere area can be evaluated after every heat. Machine vision algorithms are applied to extract estimates for the refractory wear and tuyere condition contributing to process optimization and enhanced operational efficiency.

- Electrode wear monitoring: Monitoring of electrode wear and electrode shape in AC/DC EAFs with high-resolution industrial cameras and sophisticated machine vision algorithms, ensuring optimal electrode performance and prolonged lifespan.

Benefits

Sapotech’s Reveal TAP system offers a range of significant benefits to its users:

- Real-time, high-resolution process monitoring: The Reveal TAP system provides real-time, high-detail monitoring of metal processes, offering operators and other users more detailed information of their operations.

- Intelligent algorithms and alarms: One of the features of the Reveal TAP is that it delivers in-depth information about the process, enabling the user to address specific issues before it’s too late.

- Early detection of process deviations: The system detects potential process deviations early on enabling fast corrective actions to be made.

- Data preservation and documentation: Collected process data is saved, which can be utilized for documentation and process optimization, providing valuable resources for decision-making.

- Enhanced worker safety: Through features like hot spot monitoring, the Reveal TAP system can have a huge impact on worker safety, reducing risks associated with molten metal processes.

Incorporating the Reveal TAP system into industrial settings not only optimizes operational efficiency but also fosters a safer working environment while offering robust data-driven insights for continuous process improvement.

Next Reveal TAP article will provide a more detailed insight into the system’s utilization in converter tuyere area monitoring. Don’t hesitate to contact us if you have any questions about the article. Also, stay updated on our lates news by following our LinkedIn page!