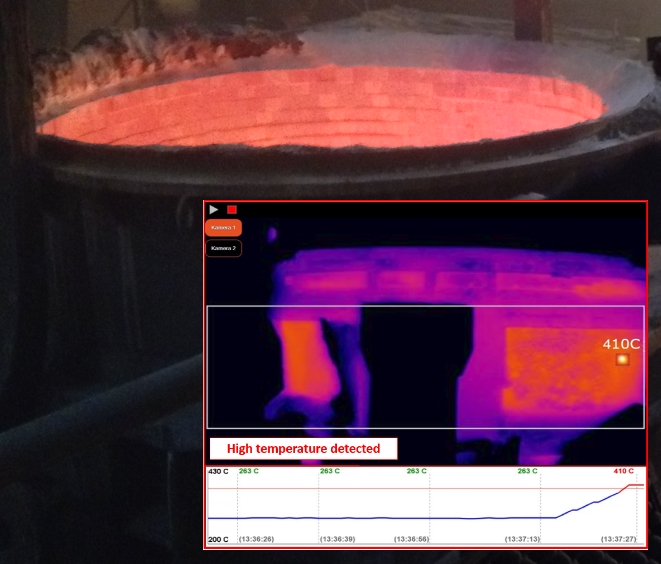

This is a new customer who wanted to improve its process operation by monitoring the temperature of the ladle outer walls and detect on time any critical heat.

Our solution

IR cameras with high resolution were used so there was a real time visualization and monitoring of the ladle outer walls. Also, all the generated data can be accessed anywhere within the plant and it was stored automatically to a cloud service for later access.

Benefits for the customer

The benefits for our customer of using Reveal TAP in this location is that the temperature of the ladle outer walls is monitored automatically. Also, any critical temperature can be detected on time to avoid accidents or unnecessary production costs. Thus, new information about the ladle condition is generated which can improve the process operations and safety.