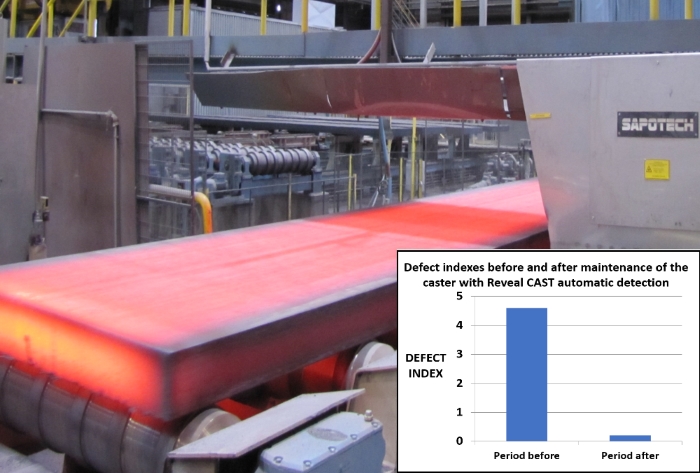

Reveal CAST has one more time proven that it not only monitors the surface condition of hot or cold products with high reliability, but also contributes to improved production efficiency at the steel plant. As an example, one of our customers has achieved extremely positive results at their casting line by utilizing Reveal CAST.

Thanks to a reliable control of their continuous casting process and the quality of produced slabs provided by Reveal CAST over the last 15 months, our customer decided to modify some caster parameters to further improve the quality of slabs. Then, they can follow the effect of the modifications in real time and verify that the changes were successful.

With these adjustments, the number of defective slabs has significantly reduced, from 1.5% to about 0.1%. Additionally, if quality problems appear again, it is very easy for maintenance personnel to react and make the necessary corrective actions, ensuring that consistent quality is maintained.